The Scientific Method has been proven over centuries to be the best approach to solve any type of complex problem. Business, which is a relatively young discipline, can learn from the scientific discipline. With science and technology, we can do almost anything.

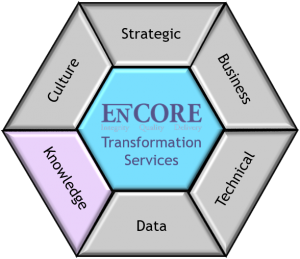

Knowledge Transformation – Empowering an organization by bringing data and analytics to life to improve and optimize decision-making and organizational performance

EnCORE’s approach is to understand what questions an organization has that can be answered with related knowledge

How to apply analytics to the knowledge to extract business-critical insights that can inform decision making, improve operations and generate value

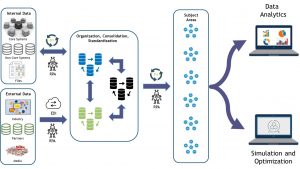

Accelerated data transformation facilitates quicker realization of expected outcomes

End-to-end process transforming source data to usable knowledge for analytics and presentation

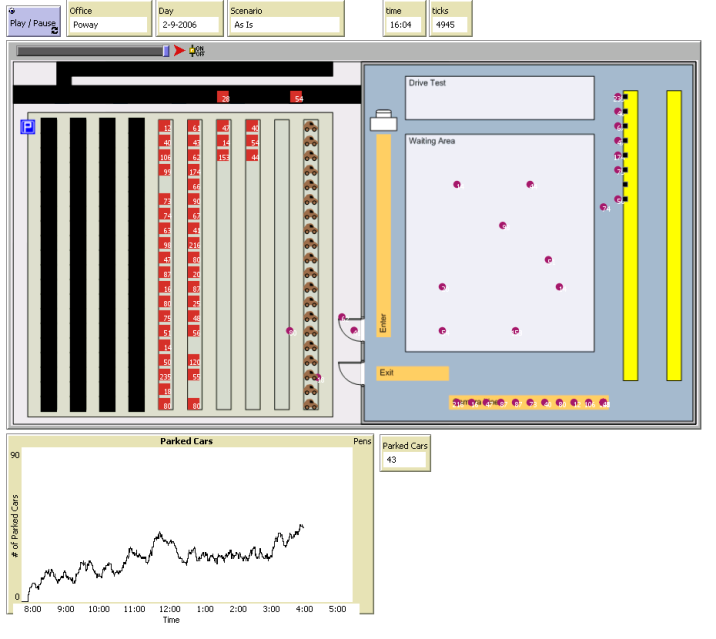

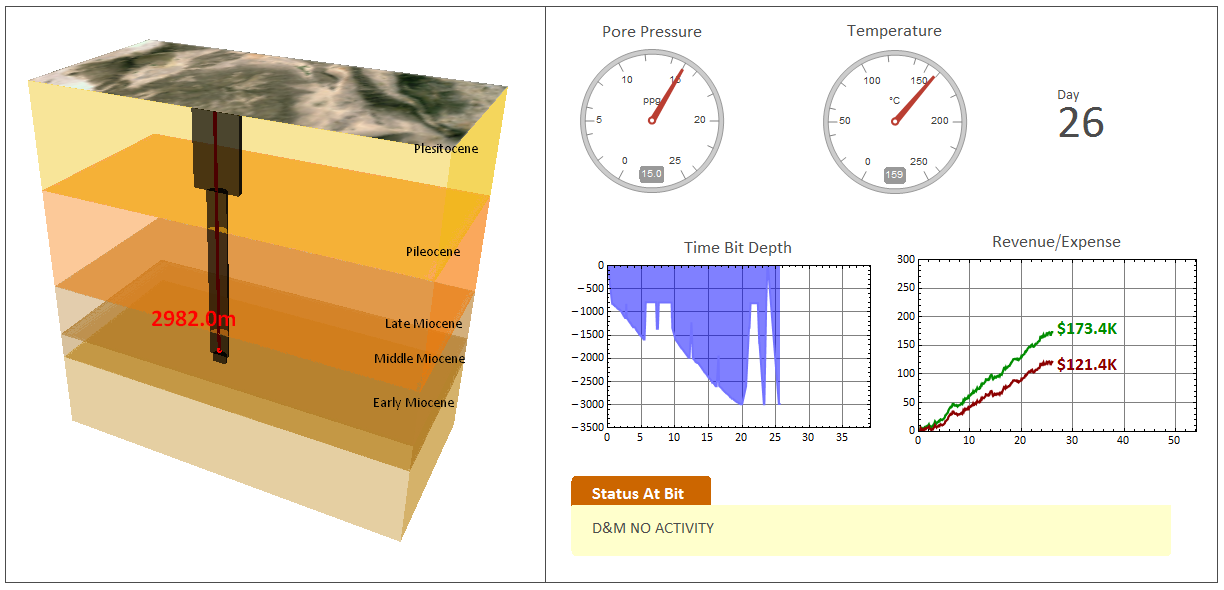

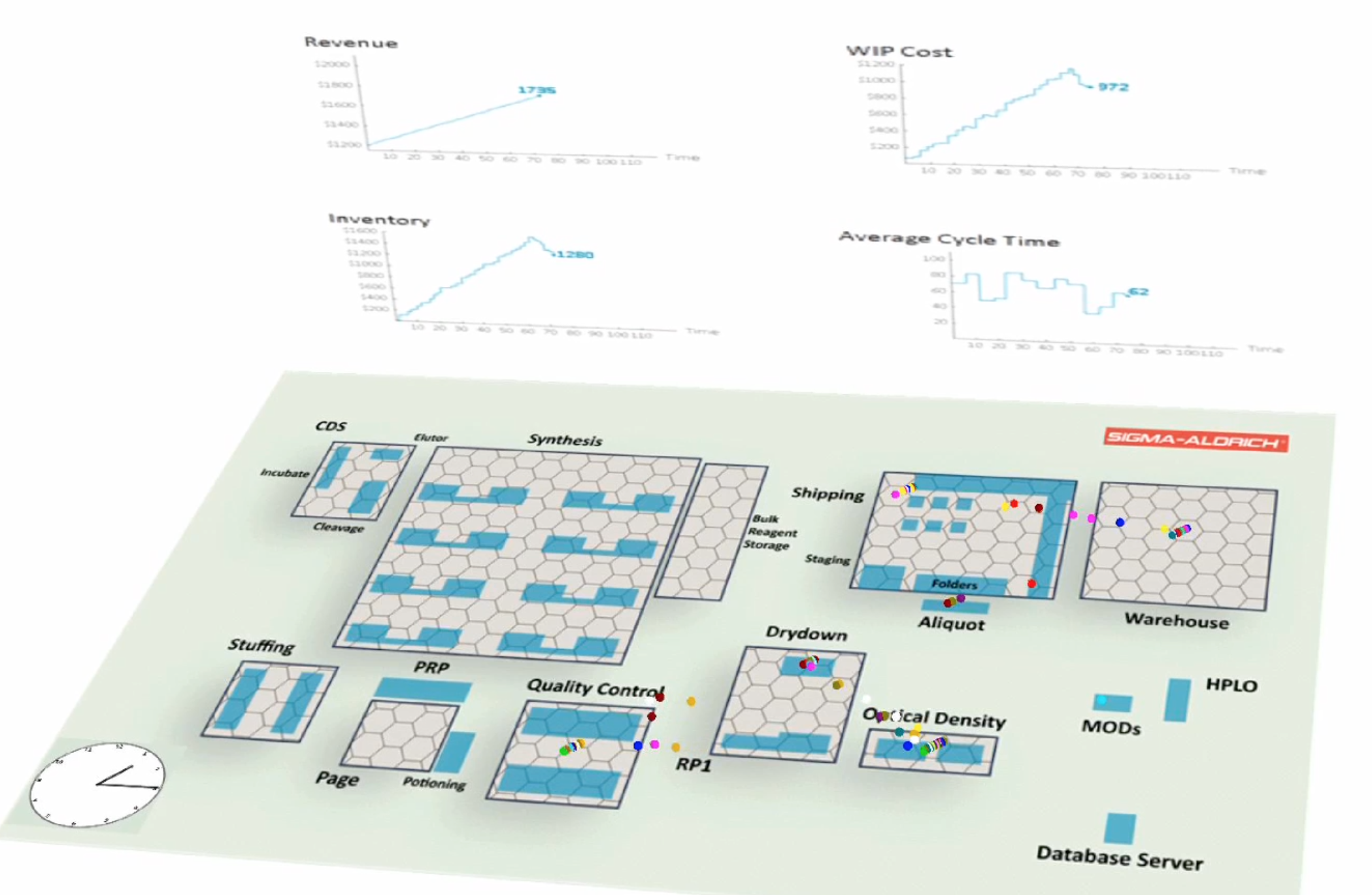

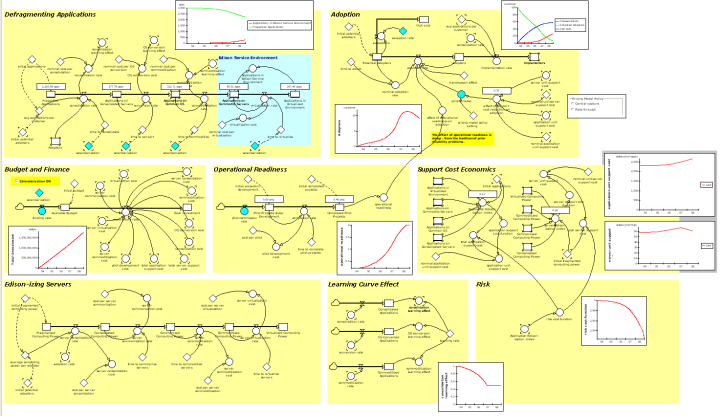

Click on the image to download and view a montage of optimization and simulation models across multiple industries.

Click on the image to download and view a montage of optimization and simulation models across multiple industries.

STRATEGY

When faced with a challenge, businesses need to determine a strategy towards approaching that challenge. However, this is a high risk endeavor, as the wrong strategy will prevent you from taking advantage of opportunities and may blindside you to possible threats. With computerized simulation, it is possible instead to run simulations for hundreds or thousands of scenarios.

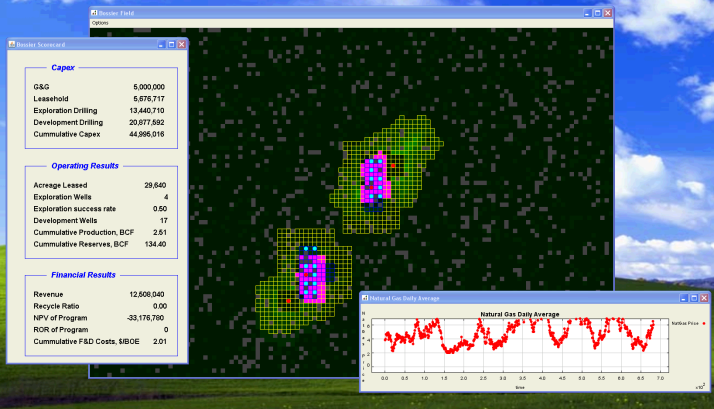

Field Development Strategy

The Question:

Are the traditional “rules of thumb” for developing natural gas fields, handed down over generations, still applicable? How can we be sure?

Our Solution:

A simulation model re-created the rules by which fields are developed, and then tested these against real field scenarios. Many long held beliefs were appropriately challenged with data.

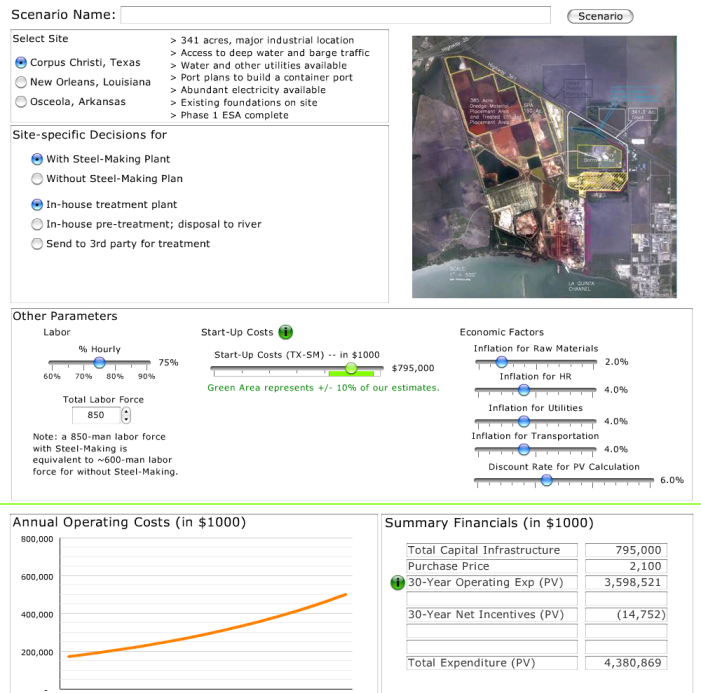

Site Selection

The Question:

A steel manufacturer based in Asia sought to locate a manufacturing facility in North America, making a choice among 35 potential sites.

Our Solution:

We incorporated all of the relevant decision factors into an analytical model, showing the impact of location on operating costs, manufacturing flexibility, and tax abatement.

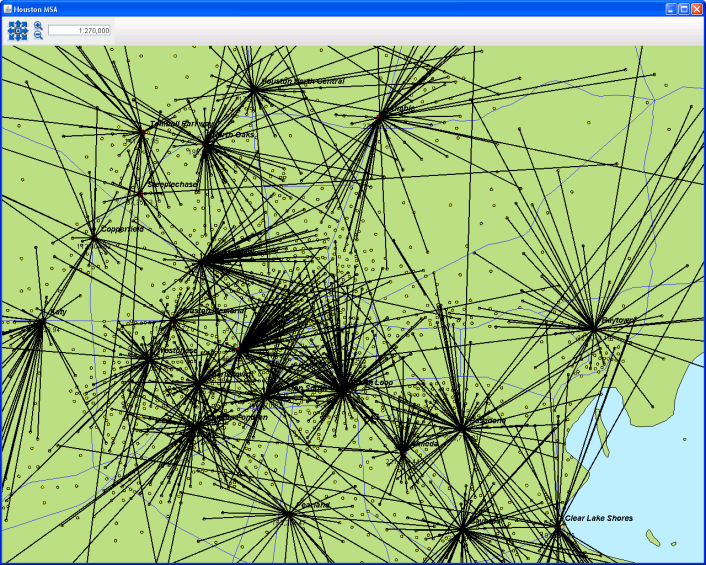

Retail Store Location

The Question:

Large national retailer committed to doubling the number of stores in its network, from 1100 to 2200. Where are the optimal locations?

Our Solution:

We incorporated known “rules” of shopper behavior with demographic data to develop a statistical profile of shoppers. The simulated shopper agents allowed us to test various store location candidates.

COST ANALYSIS

How much did that cost?” is far more complicated to answer today than it ever has been. When making business decisions, it can be complicated to determine the actual direct and indirect cost of a particular activity. Reality is complicated and it is easy to overlook “invisible” costs until it is too late and the company is committed to a particular course of action – inefficiencies detected only in hindsight.

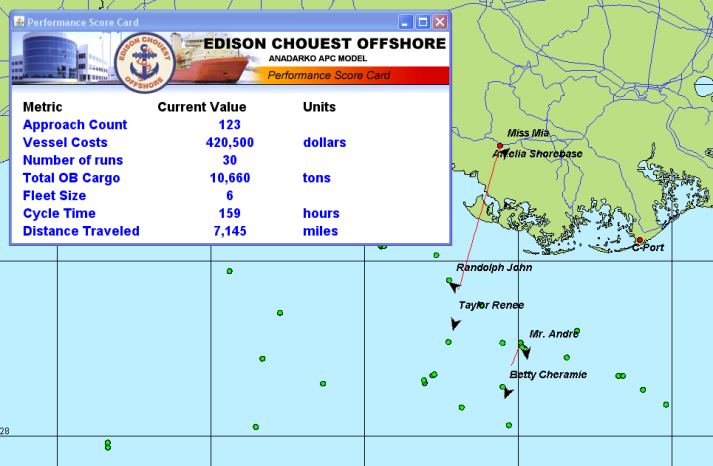

Marine Logistics

The Question:

Offshore energy production facilities require a steady stream of materials delivered by boat. A missed or late delivery could have a substantial cost impact.

Our Solution:

A simulation model was created as a shared collaboration between the service provider and the offshore customer. Each contributed to the “lean service” optimization of the logistics fleet.

CalDMV: Simulation of Customer Interactions

The Question:

California DMV sought to reduce the cost of serving its customers while improving overall service level and satisfaction.

Our Solution:

A simulation model allowing DMV to understand the interaction of DMV office locations, staff resource levels, and the use of self-help kiosks, against several customer makeup scenarios.

Rail Network Scenario Planning

The Question:

Producer of aggregate (rock) expands production at the main quarry. Will the proposed commuter rail line restrictions prevent the company from getting a return on its capital?

Our Solution:

Our simulation showed the company that a series of minor alterations in route structure and timing would allow full throughput of product to customers.

FORECASTING

If the future is uncertain, how do you plan for it? Forecasting based on simulated models allow you to see how the systems at work in the environment around the company will likely influence the future of the company. While a singular definitive future is unlikely to emerge, forecasting allows you to see which of all possible futures are likely and plausible.

Big Data for Drilling

The Question:

Thousands of individual oil and gas wells exist in the company’s portfolio. What patterns exist in the histories of these wells that shed light on the characteristics of future wells?

Our Solution:

We created a data science tool that allowed engineers to recreate past well drilling operations and even search for commonalities across history.

Merger Integration

The Question:

A pharma company is considering a merger with another firm. The linchpin of the merger is the consolidation of two product lines within one manufacturing site. Could it be done?

Our Solution:

The model showed a problem in consolidating the two products. After some experimentation with layout, staffing, and scheduling, the merger integration team found a way to make consolidation work.

Modeling IT Transformation

The Question:

A Big 3 automotive firm was about to embark on an ambitious 5 year remake of its IT organization. How can the success of this program be assured?

Our Solution:

Program initiatives were translated into a model of the transformation, including the human behavior aspect. The model was used to role play through unexpected events in the project.

OPTIMIZATION

If your business model is not well understood, simulation allows you to change the parameters and see how the business behaves under those parameters. Through simulation, you can change the parameters of your business model to see how it behaves under a variety of situations. With this experience, you can then move on to optimization – getting the greatest possible reward for the least possible cost.

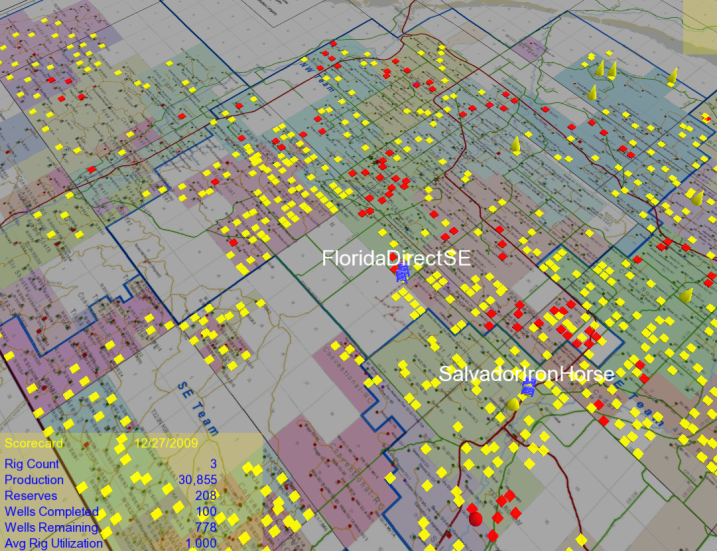

Portfolio Optimization

The Question:

Energy company with over 1100 natural gas wells to be drilled. What is the right sequence of drilling that maximizes the value of the field?

Our Solution:

The simulation model allowed the experts to apply different rules to the choices of “which well next”. The resulting experimentation led the team to consider and assess several choices before settling on an optimal drilling plan.

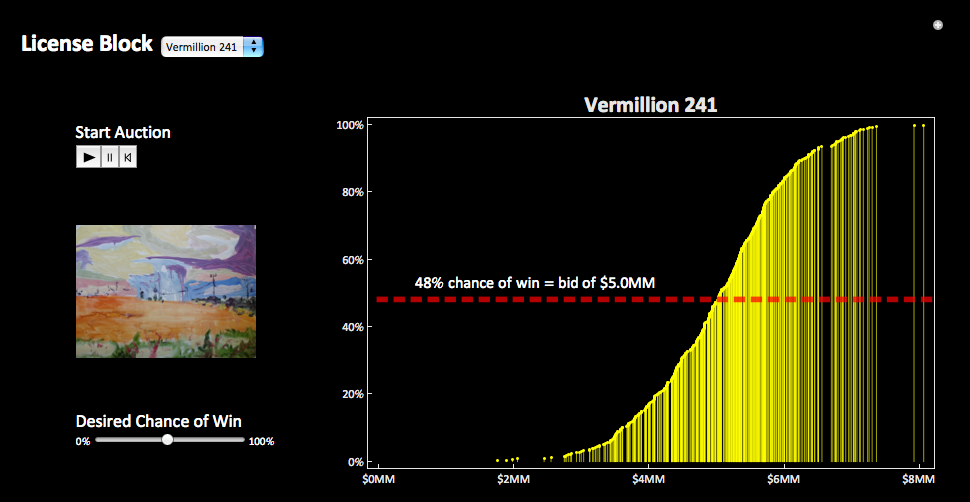

Monte Carlo Simulation

The Question:

The company needed a data-driven way to determine the appropriate bid for offshore drilling rights. The current process was highly subjective.

Our Solution:

A model simulates thousands of possible auctions and shows the probability of win at various bid levels.

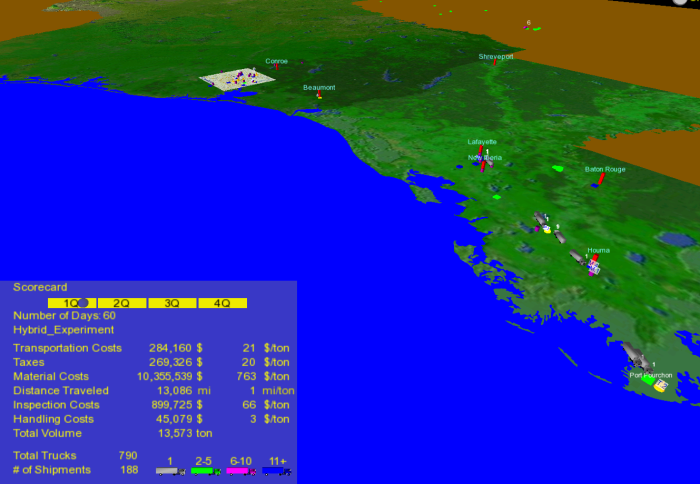

Material Supply Chain

The Question:

The merger of two major energy companies created enormous inefficiencies in their respective supply chains.

Our Solution:

We simulated one year of the operation of the two supply chains, guiding the team to the optimal combination of facilities and locations.

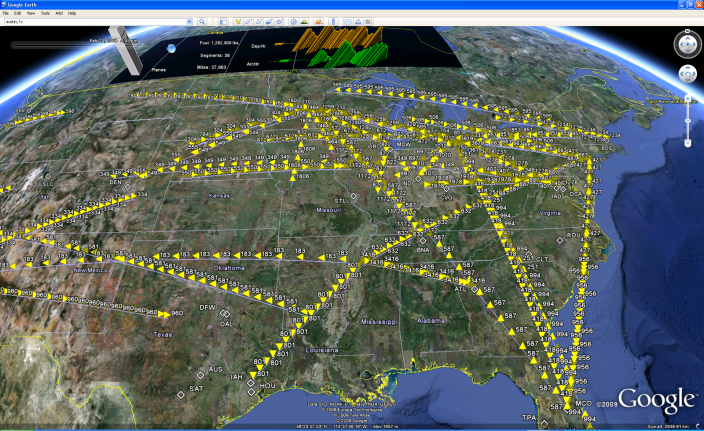

Optimization of Jet Fuel Costs

The Question:

A US national air carrier sought to compete by becoming the smartest jet fuel buyer in the industry.

Our Solution:

Create a simulation model of the route system so that intricate buying/refueling strategies could be developed and tested.